What are SIPs?

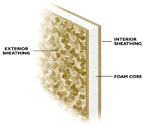

SIPs are the 21st Century Building Material, Structural insulated panels (SIPs) are high performance building panels used in floors, walls, and roofs for residential and light commercial buildings. The panels are typically made by sandwiching a core of rigid foam plastic insulation between two structural skins of oriented strand board (OSB). Other skin material can be used for specific purposes. SIPs are manufactured under factory controlled conditions and can be custom designed for each home. The result is a building system that is extremely strong, energy efficient and cost effective. Building with SIPs will save you time, money and labor.

Are Structural Insulated Panels More Expensive?

Building with SIPs generally costs about the same as building with wood frame construction, when you factor in the labor savings resulting from  shorter construction time and less job-site waste.

shorter construction time and less job-site waste.

Other savings are realized because less expensive heating and cooling systems are required with SIP construction.

Dry wall or dense board is used for the interior skin of the panels and treated for mold. It has a one hour fire rating, sound resistance and R rating savings that surpass any conventional building. Concrete skin panel designed for exterior or interior application can be treated with one coat stucco or other coating if desired.

Forty years of industry testing, working with builders, developers and assisting them in the field, code compliance, state government, building and planning departments has gone into the development of Super Struct’s building process. Super Struct Building, Inc. has engineered, planned, designed and processed plans for construction, including construction financing and purchasing and manufacturing the materials to build.

Forty years of industry testing, working with builders, developers and assisting them in the field, code compliance, state government, building and planning departments has gone into the development of Super Struct’s building process. Super Struct Building, Inc. has engineered, planned, designed and processed plans for construction, including construction financing and purchasing and manufacturing the materials to build.

This technology for manufacturing homes can be set up anywhere with a large order of 200 or more homes. With small kit homes, the pricing is very affordable. See Home Pricing for more information.

SIPs Out Perform”Stick Built”

SIP buildings are vastly more energy efficient, stronger, quieter, and more draft free than other building systems, such as stud framing with fiberglass insulation. Fiberglass is sometimes used for furnace filters because air moves through so freely. Rigid insulation is used as solid component insulation in almost every industry for its inherent efficiency and lack of air movement. These attributes are built right into a SIP building. Less air leakage means fewer drafts, less noise, lower energy bills, and a much more comfortable indoor environment.

SIP buildings are vastly more energy efficient, stronger, quieter, and more draft free than other building systems, such as stud framing with fiberglass insulation. Fiberglass is sometimes used for furnace filters because air moves through so freely. Rigid insulation is used as solid component insulation in almost every industry for its inherent efficiency and lack of air movement. These attributes are built right into a SIP building. Less air leakage means fewer drafts, less noise, lower energy bills, and a much more comfortable indoor environment.